The Rare Earth Dilemma

Why Rare Earth Elements Are Suddenly Everyone’s Problem (and How Startups Are Solving It)

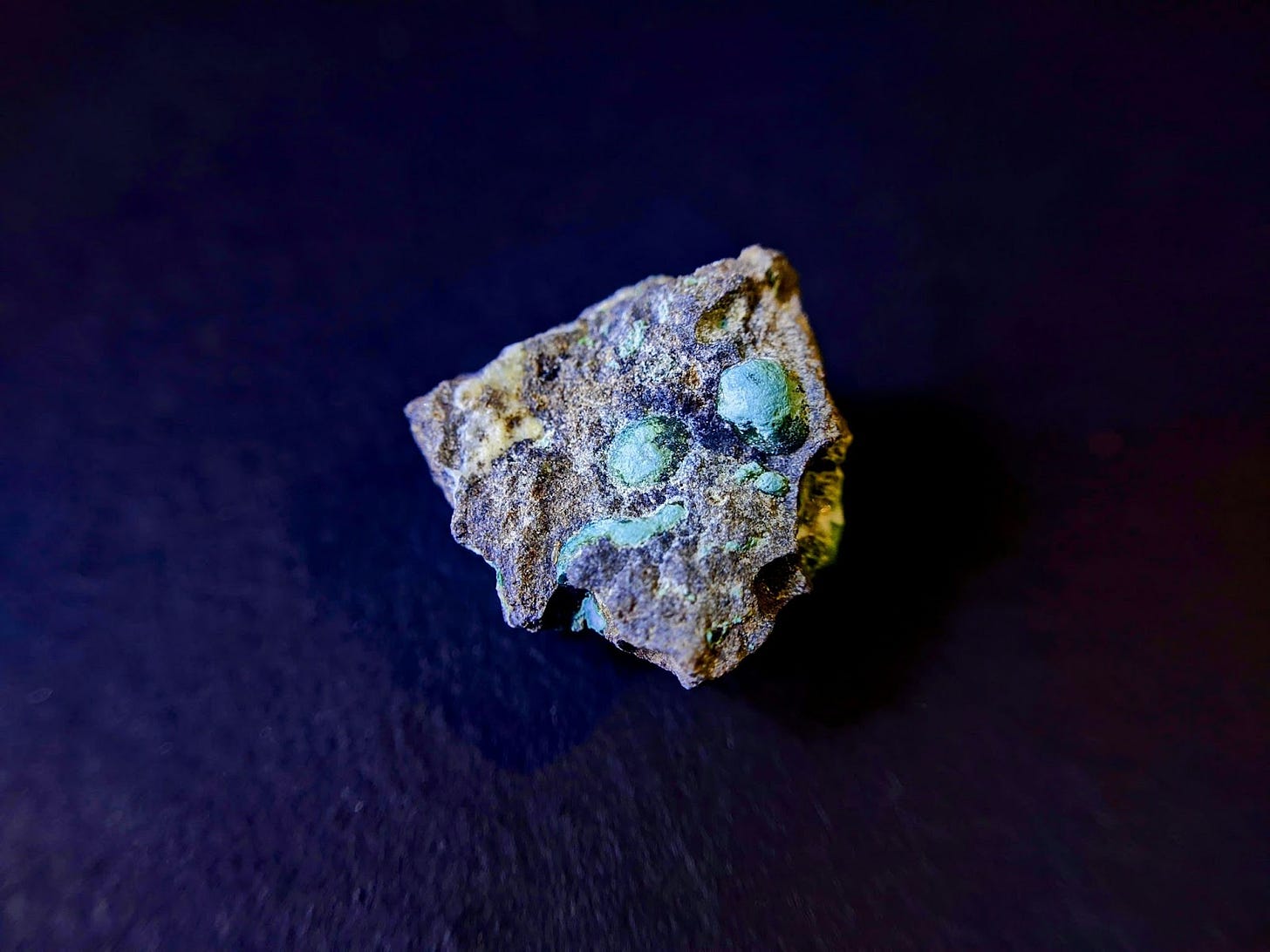

Rare earth elements (REEs) are having a moment - and not just in mining journals. Unless you have been living under a rock, you have heard about the looming shortages in REEs (we will not go into the geopolitical discussions here).

From EVs and smartphones to wind turbines and quantum displays, these metals are at the heart of modern technology. But they come with messy, often overlooked downsides - environmental destruction, supply chain bottlenecks, and geopolitical risk.

Yet, as with so many of today’s complex problems, startups are at the center of some of the most promising solutions.

Let’s break down what REEs are, why they matter, and how emerging companies are reimagining the future of this crucial sector.

Image credit: PAVAN JAMDAR on Unsplash

What Are Rare Earth Elements?

Rare earth elements are a group of 17 similar heavy metals. Despite the name, they’re not all that rare in terms of abundance. What makes them “rare” is how hard it is to find them in concentrations that make economic sense to mine.

The process of mining and refining these elements degrades the environment, and often comes with radioactive byproducts like thorium and uranium. In regions with weak environmental oversight, this creates major ecological and human health hazards.

Where Do We Use Them?

The single biggest use of REEs? Permanent magnets.

These are used in electric vehicle (EV) motors and wind turbine generators. REEs also show up in:

Smartphones (screens, speakers, microphones)

Internal combustion engine (ICE) vehicles (in catalytic converters)

Display technology (those vivid colors - they come from REEs)

Quick refresher: In electric motors, permanent magnets work alongside current-carrying coils. The interaction between the electromagnetic fields of the coils and the magnet creates torque, which is harnessed to rotate the wheels of your EV.

Remove the REEs, and the EV architecture breaks down - at least for now, until a solution is found.

The Problem with REEs

The global demand for REEs is soaring. But so are the challenges:

Environmental cost: Extracting REEs generates toxic waste and radioactive byproducts.

Geopolitical tension: Supply is concentrated in a handful of countries, making global access uncertain.

Recycling difficulty: Recovering REEs from used devices is both technically and economically challenging.

If we want to build a cleaner and more resilient future, we need to:

Use fewer REEs,

Recycle what we’ve already extracted, and

Find viable, scalable alternatives.

Startups Taking on the Rare Earth Challenge

Fortunately, a wave of innovation is tackling the REE problem from multiple angles. Here are a few standout startups:

Niron Magnetics

HQ: Minnesota, USA

Funding: $161.6M

What they do: Niron is developing Clean Earth Magnets using iron nitride—an REE-free material with comparable magnetic strength. Backers include General Motors Ventures, Stellantis Ventures, and Samsung Ventures.

Phoenix Tailings

HQ: Massachusetts, USA

Funding: $76.7M

What they do: Phoenix Tailings extracts REEs like neodymium from mining waste instead of fresh ore, using a clean, closed-loop process.

Turntide Technologies

HQ: California, USA

Funding: $491.5M

What they do: Turntide builds ultra-efficient electric motors that eliminate or drastically reduce the need for REEs. Their “Smart Motor System” is used in HVAC systems and EVs.

Nanosys

HQ: California, USA

Funding: $246.7M

What they do: Pioneers in quantum dot displays, Nanosys replaces REE-based phosphors with indium phosphide. Their technology is already in millions of TVs and monitors.

Ionic Technologies

HQ: Belfast, UK

Founded: 2022

What they do: Developing high-purity recycling of REEs from end-of-life magnets using ionic liquids—a step toward a circular economy for rare earths.

MagREEsource

HQ: Rhône-Alpes, France

Funding: €5M

What they do: Uses hydrogen-based tech to recycle and remanufacture permanent magnets. Aiming to reduce dependence on virgin REEs.

What’s Next?

The road ahead is still long. But the direction is clear. If we want to make advanced technologies sustainable at scale, the rare earth problem has to be solved.

That means:

Designing with less: Rethink motors, magnets, and material systems to reduce reliance on REEs.

Recycling smarter: Develop affordable and scalable methods to recover REEs from used products and waste.

Substituting strategically: Double down on alternatives like iron nitride, indium phosphide, and other advanced materials.

The world needs cleaner magnets, smarter motors, and better mining alternatives, and startups are leading the charge.

If you’re building something in this space, I’d love to hear from you.

One more I was reading about yesterday is AlkaLi Labs - https://www.alkalilabs.com/